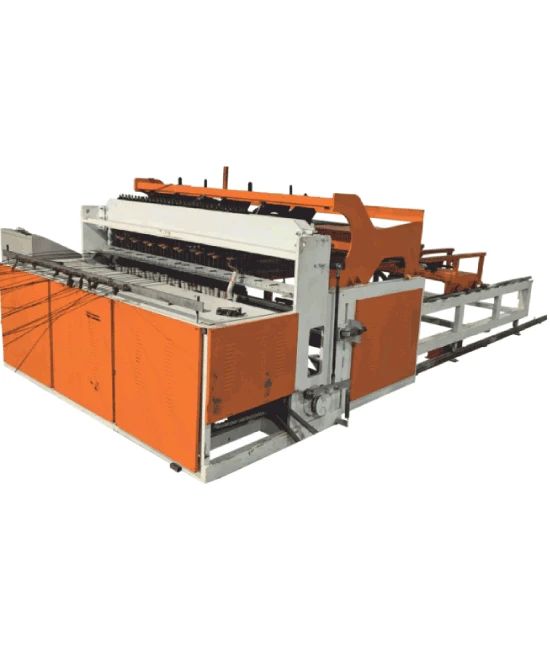

Automatic Sheet Expanded Mesh Machine

Automatic Sheet Expanded Mesh Machine for Durable Metal Mesh

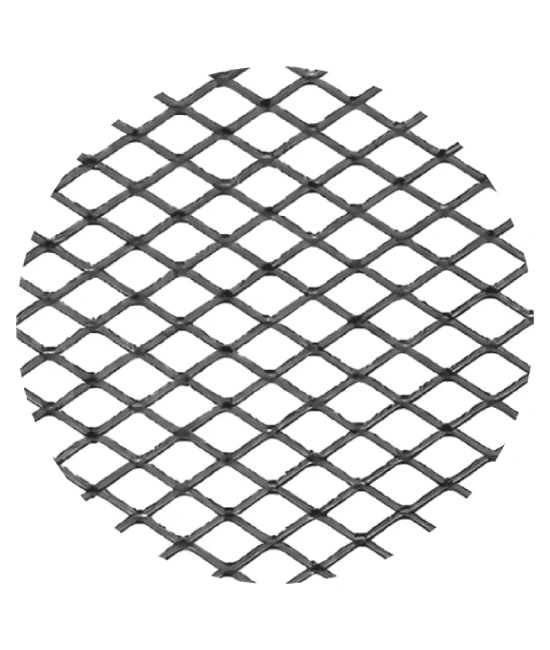

An Automatic Sheet Expanded Mesh Machine is a specialized industrial machine designed to produce expanded metal mesh from sheet materials like steel, aluminum, or other metals. The machine stretches and cuts metal sheets to form diamond-shaped or other geometric mesh patterns.

Metal sheets are automatically fed into the machine. The machine slits the sheet and simultaneously stretches it, creating a mesh pattern with interconnected strand. The process transforms the solid sheet into an expanded, open-grid structure without material loss, enhancing strength and rigidity.

The expanded mesh is then cut to specified dimensions. This machine is widely used in industries like construction, filtration, and security, where expanded mesh is used for fencing, facades, and reinforcement applications. Its automated function increases production speed and ensures consistent quality and precision.

Automatic Sheet Expanded Mesh Machine

Automatic Sheet Expanded Mesh Machine for Durable Metal Mesh

An Automatic Sheet Expanded Mesh Machine is a specialized industrial machine designed to produce expanded metal mesh from sheet materials like steel, aluminum, or other metals. The machine stretches and cuts metal sheets to form diamond-shaped or other geometric mesh patterns.

Metal sheets are automatically fed into the machine. The machine slits the sheet and simultaneously stretches it, creating a mesh pattern with interconnected strand. The process transforms the solid sheet into an expanded, open-grid structure without material loss, enhancing strength and rigidity.

The expanded mesh is then cut to specified dimensions. This machine is widely used in industries like construction, filtration, and security, where expanded mesh is used for fencing, facades, and reinforcement applications. Its automated function increases production speed and ensures consistent quality and precision.

Product Specification

Automatic Sheet Expanded Mesh Machine: Superior Quality and Efficient Mesh Production

Machine Type:

-

Fully automatic sheet punching machine designed for high-speed production.

Sheet Thickness:

-

Handles sheet thickness from 0.2 mm to 4.0 mm, offering versatility for various applications.

Sheet Width:

-

Capable of processing sheets up to 2 meters wide, ideal for large-scale production.

Power Press Capacity:

-

Offers two power press capacity options: 120 Ton or 165 Ton, providing powerful and precise punching performance.

Punching Speed:

-

Performs between 100 to 200 punches per minute, ensuring rapid and efficient production cycles.

Production Capacity:

-

Production output varies depending on mesh size, offering flexible production capacity for different project needs.

Power Requirements:

-

Operates with a power supply of 25 HP, 3-phase, 440V for consistent and reliable performance.

Manpower Requirements:

-

Requires only 2 persons per shift, optimizing labor usage and reducing operational costs.

Control System:

-

Equipped with an advanced PLC control system with HMI and Servo Drive for precise control, enhanced automation, and easy operation.