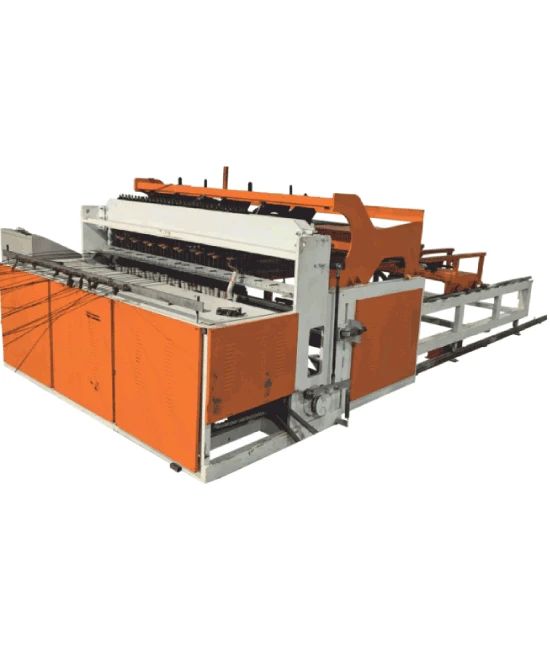

Automatic Welded Wire Mesh Machine

Automatic Welded Wire Mesh Machine for High-Speed Production

Both longitude wire and cross wire were feeding from wire coils automatically. The raw material is applicable for low-carbon steel wire or stainless-steel wire. It has advantages such as design reasonable, low noise, more stable, easier to operate and Electro-Magnetism Adjustable speed for welding. The mesh size is precise, and the machine can be set the width of length according to the customer’s requirement. It’s made up of a main welding machine, electrical control cabinet, repair table, repair machine, bracket for longitude wires, wire rolling machine and plastic rollers.

-

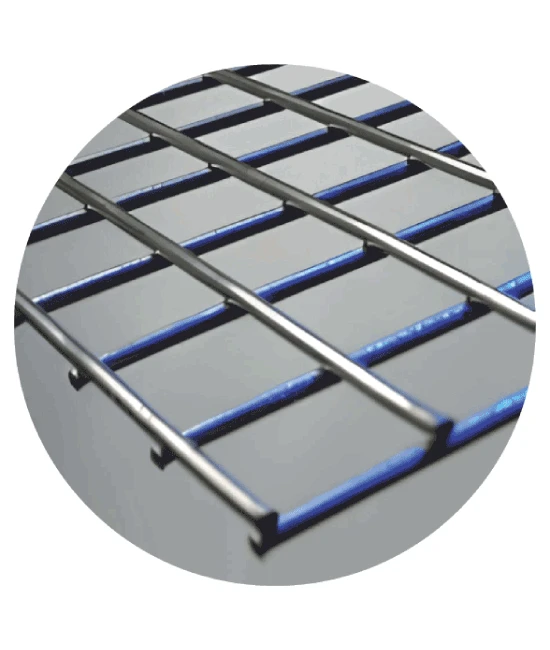

Wire diameter: 1.5 mm to 2.8mm (Between any size Adjustable)

-

Mesh Hole Size- 25*25mm to 175*175mm (Adjustable)

-

Mesh Width: Max. 2 Meter. (Adjustable)

-

Welding speed: about max 80 times per minute (Depending on Hole size)

-

Mesh rolling length: 100m

-

Welding Transformer: 85Kva * 7 (Depended on Wire diameter and hole size

-

Input Power: 415V,50HZ, 3 Phase or according to client’s requirement 440v

-

Weight: 4500 Kg

-

Machine Working space required. - 80ft*25ft*10ft (L*W*H)

Automatic Welded Wire Mesh Machine

Automatic Welded Wire Mesh Machine for High-Speed Production

Both longitude wire and cross wire were feeding from wire coils automatically. The raw material is applicable for low-carbon steel wire or stainless-steel wire. It has advantages such as design reasonable, low noise, more stable, easier to operate and Electro-Magnetism Adjustable speed for welding. The mesh size is precise, and the machine can be set the width of length according to the customer’s requirement. It’s made up of a main welding machine, electrical control cabinet, repair table, repair machine, bracket for longitude wires, wire rolling machine and plastic rollers.

-

Wire diameter: 1.5 mm to 2.8mm (Between any size Adjustable)

-

Mesh Hole Size- 25*25mm to 175*175mm (Adjustable)

-

Mesh Width: Max. 2 Meter. (Adjustable)

-

Welding speed: about max 80 times per minute (Depending on Hole size)

-

Mesh rolling length: 100m

-

Welding Transformer: 85Kva * 7 (Depended on Wire diameter and hole size

-

Input Power: 415V,50HZ, 3 Phase or according to client’s requirement 440v

-

Weight: 4500 Kg

-

Machine Working space required. - 80ft*25ft*10ft (L*W*H)

Product Specification

Premium Chain Link Fencing and Wire Welded Machines – Hindustan Corporation

Model Types:

-

FW-1, FW-2, FW-3: Fully Automatic Machines

-

SW-A, SW-B, SW-C: Semi-Automatic Machines

Control System:

-

FW-1, FW-2: Controlled by VFD (Variable Frequency Drive)

-

FW-3: Controlled by VFD/PLC

-

SW-A, SW-B, SW-C: Controlled by VFD/Servo/PLC systems for enhanced accuracy

Wire Size Range:

-

FW-1: Handles wire sizes from 0.5 mm to 2.0 mm

-

FW-2: Accommodates wire sizes from 1.0 mm to 2.8 mm

-

FW-3: Supports wire sizes from 1.0 mm to 3.0 mm

-

SW-A: For wire sizes 3.0 mm to 6.0 mm

-

SW-B: Handles wire sizes 3.0 mm to 6.0 mm

-

SW-C: Supports larger wire sizes from 5.0 mm to 12.0 mm

Mesh Width Capacity:

-

FW-1, FW-2, SW-B: Maximum mesh width of 2.5 meters

-

FW-3, SW-A, SW-C: Maximum mesh width of 2.0 meters and 3.0 meters, respectively

Mesh Pitch (Hole Size):

-

FW-1: Mesh pitch adjustable from 10 mm to 30 mm

-

FW-2: Mesh pitch adjustable from 25 mm to 125 mm

-

FW-3: Mesh pitch adjustable from 25 mm to 150 mm

-

SW-A: Mesh pitch from 25 mm to 200 mm

-

SW-B: Mesh pitch from 50 mm to 200 mm

-

SW-C: Mesh pitch adjustable from 75 mm to 500 mm

Wire Feeding Mechanism:

-

FW-1, FW-2, FW-3: Direct feeding from the coil for both line and cross wires

-

SW-A, SW-B: Line wire direct from coil, cross wire pre-cut

-

SW-C: Both line and cross wires pre-cut

Wire Material Supported:

-

FW-1, FW-2: Supports galvanized iron (GI) wire

-

FW-3: Supports GI and mild steel (MS) wires

-

SW-A, SW-B: Supports GI and MS wires

-

SW-C: Supports GI, MS, and Rebar wire materials

Power Requirements:

-

FW-1: 40 kW

-

FW-2: 45 kW

-

FW-3: 60 kW

-

SW-A: 65 kW

-

SW-B: 85 kW

-

SW-C: 200 kW

Production Capacity:

-

FW-1: Up to 120 rows per minute

-

FW-2: Up to 80 rows per minute

-

FW-3: Up to 60 rows per minute

-

SW-A, SW-B: Up to 60 rows per minute

-

SW-C: Up to 60 rows per minute

Manpower Requirements:

-

FW-1, FW-2, FW-3: Requires 2 operators

-

SW-A, SW-B: Requires 4 operators

-

SW-C: Requires 5 operators