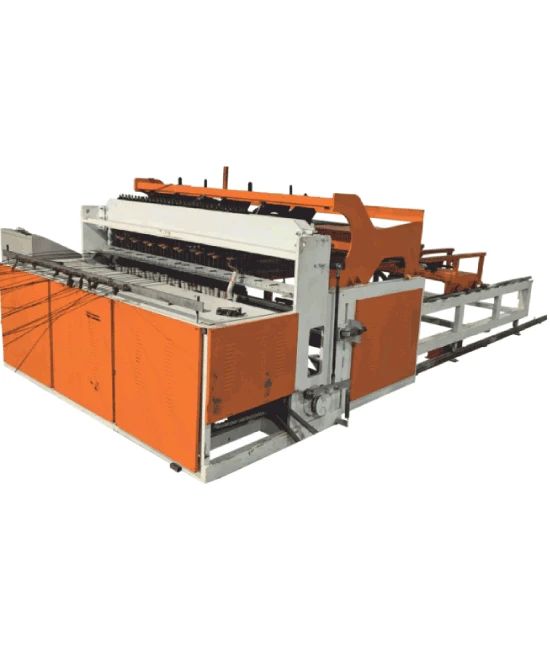

Automatic Concertina Wire Making Machine

Automatic Concertina Wire Making Machine for Secure Fencing

This fully automatic dryer is mainly to match the fully automatic tube coiling machine. The semi-finished paper bobbin coiled by tube coiling machine set is automatically and synchronously inserted on the dryer conveying chains and conveyed to drying chamber for drying. After 34- 26mins, paper bobbin is delivered out from drying box.

The paper bobbins are automatically taken and inserted into strings by counting without manual operation. The heater has automatic temperature control. This dryer can contain 1450 paper bobbins and the drying time is 34-36mins.

This dryer adopts channel steel machine frame, customized chains and chain wheels. Spring with high accuracy is adopted for inserted paper bobbin positioning and heat retaining panels are used for the four sides. Main machine use the geared motor to drive chains for conveying and drying.

The electrical heating and steam heating can be adopted inside drying box. The internal temperature can be shown by instrument (chosen by user). Control temperature and heating mode automatically as needed. For electrical heating, use the electrical heated tube heating in three sets with every set of 6KW and 18.2KW in total. Heating inside the dryer can ensure automatic temperature control with low energy consumption and good overall efficiency.