Automatic Hexagonal Wire Mesh Machine

Automatic Hexagonal Wire Mesh Machine for High-Quality Mesh Production

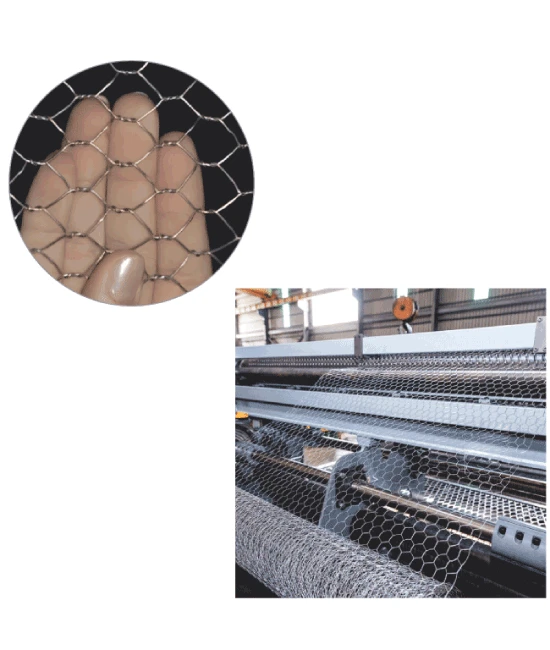

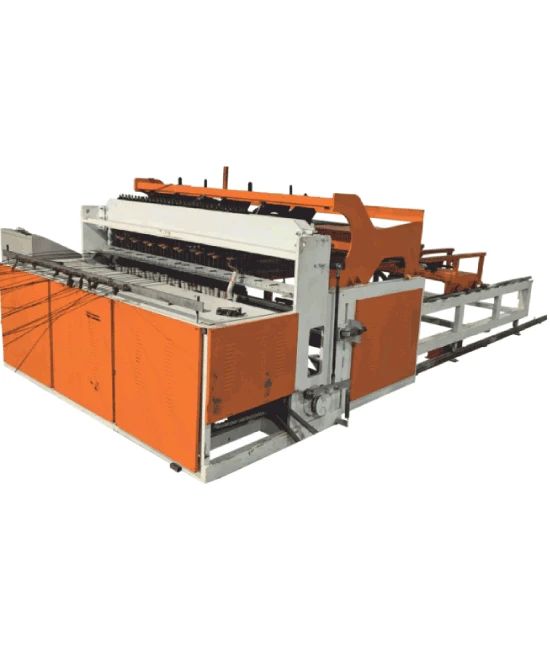

An Automatic Hexagonal Wire Mesh Machine is designed to produce hexagonal wire mesh, commonly known as chicken wire, used for fencing, animal enclosures, and reinforcement in construction. Galvanized or PVC-coated wires are fed into the machine automatically. The machine weaves the wire into a continuous hexagonal mesh pattern by twisting the wires together at regular intervals.

Once the desired length is reached, the machine automatically cuts the mesh. The completed hexagonal mesh is rolled for easy handling and transportation. This machine offers high production speed, uniform mesh size, and durability, making it ideal for large-scale production in industries requiring fencing, insulation, or gabion baskets. The automation ensures precision and reduces labor costs.

The fully automatic nature of this machine enhances production speed, reduces labor costs, and ensures uniformity in the mesh structure, making it a vital tool in the fencing and construction industries. The machine automatically feeds wire coils into the system, which can be made from materials like galvanized steel or stainless steel.